Details

Importance Of woven packaging

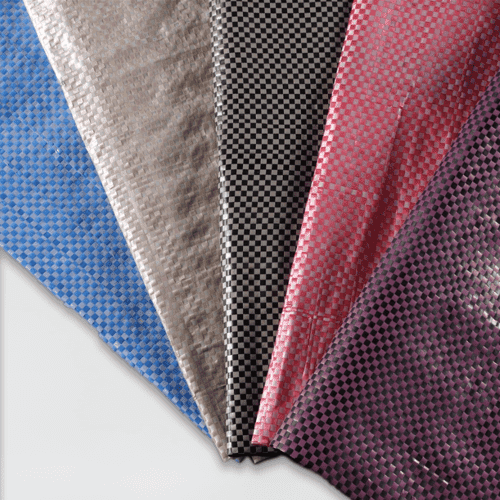

Fabric in woven packaging is as important as bricks and cement in the construction of buildings. Without fabric, woven packaging would be the next impossible thing on earth unless we get some other viable alternative. There are many important things that matter in the production of Fabric. Our years of experience help us manufacture the best quality fabric with the help of various techniques such as customized recipes, unique product codes and so on. Apart from that the denier, color, thickness, and the mesh are very much important in it.

Manufacturing Process

In the manufacturing process, our looms play an important part. A tubular or flat fabric is made by weaving the PP/HDPE tapes. During the process, the tension of warped tapes is regulated by the load cell. There is an in-feed system which controls the speed of the inlet rollers during weaving as per set tension. Also, the fabric roll winder equipped with a load cell ensures that the winding tension of fabric remains uniform throughout the process. This is how we get our final product which is PP Woven Fabric.

Material Combination

The real material used to make the fabric is PP/HDPE granules. With granules, the tapes are made and these tapes after getting weaved forms the fabric. The advance machinery in our plant ensures that our customers get the top quality fabric in their bags. Since all this process is based on the calculations and material ratio, we make sure that no quality issues arise during the process.

Latest Trends

Today we have all sorts of fabric made from different materials, but there is something unique about the PP (Polypropylene) and HDPE (High-density Polyethylene). Started from the United Kingdom in the 30s, PP and HDPE just skyrocketed in popularity and currently, it is the most versatile material used in literally everything. Manufactured by sticking together ethylene molecules (now you know why it is called ‘ethylene’), PP and HDPE are very popular for its vivid applications. Being one of the most flexible, it is lightweight yet super durable. In addition to features like impact resistance, durability, malleability, it is a recyclable fabric material as well. Even this recycled material possesses the same features and uniqueness that a new PP or HDPE fabric has.